Industry 4.0

Always innovating

and in evolution

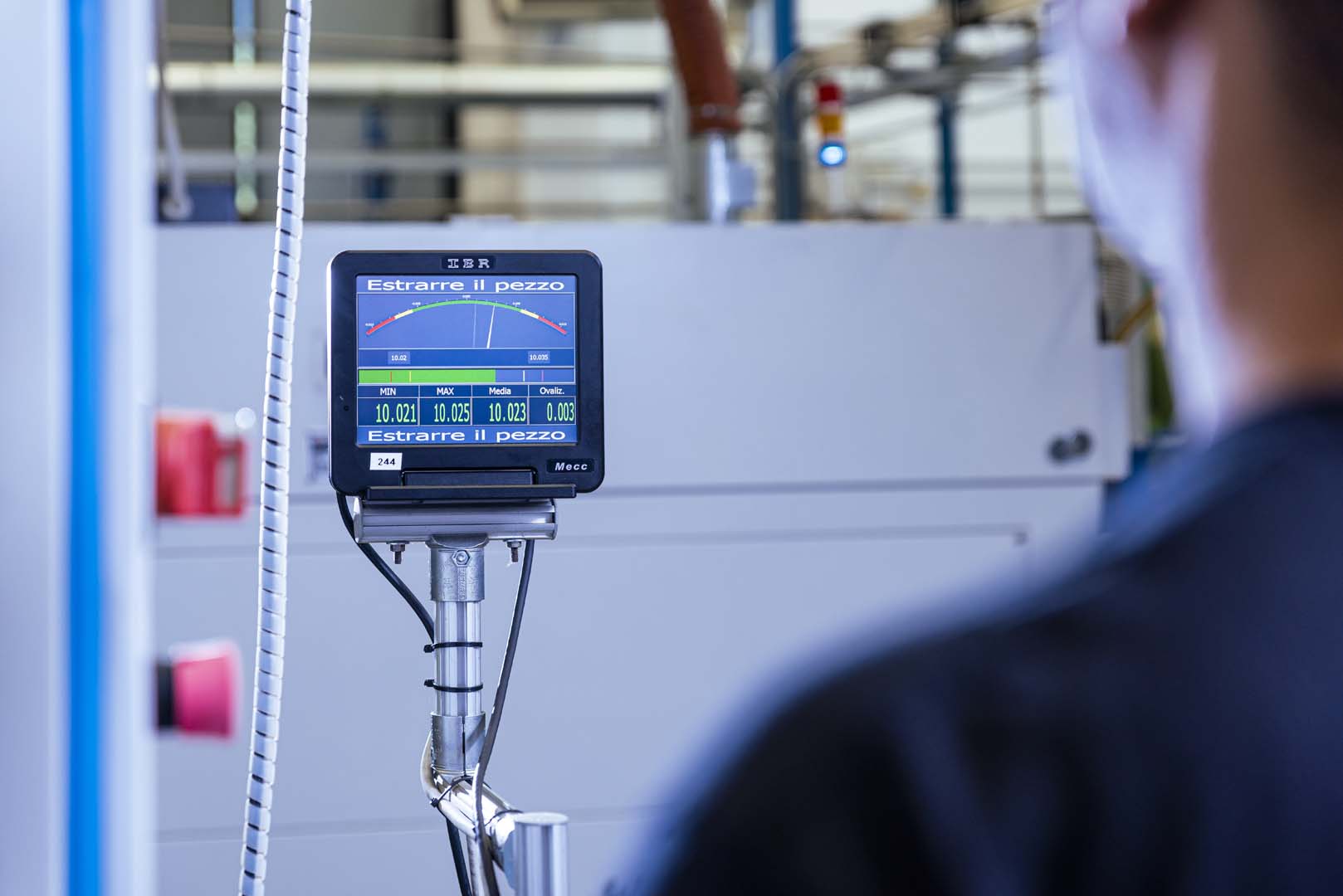

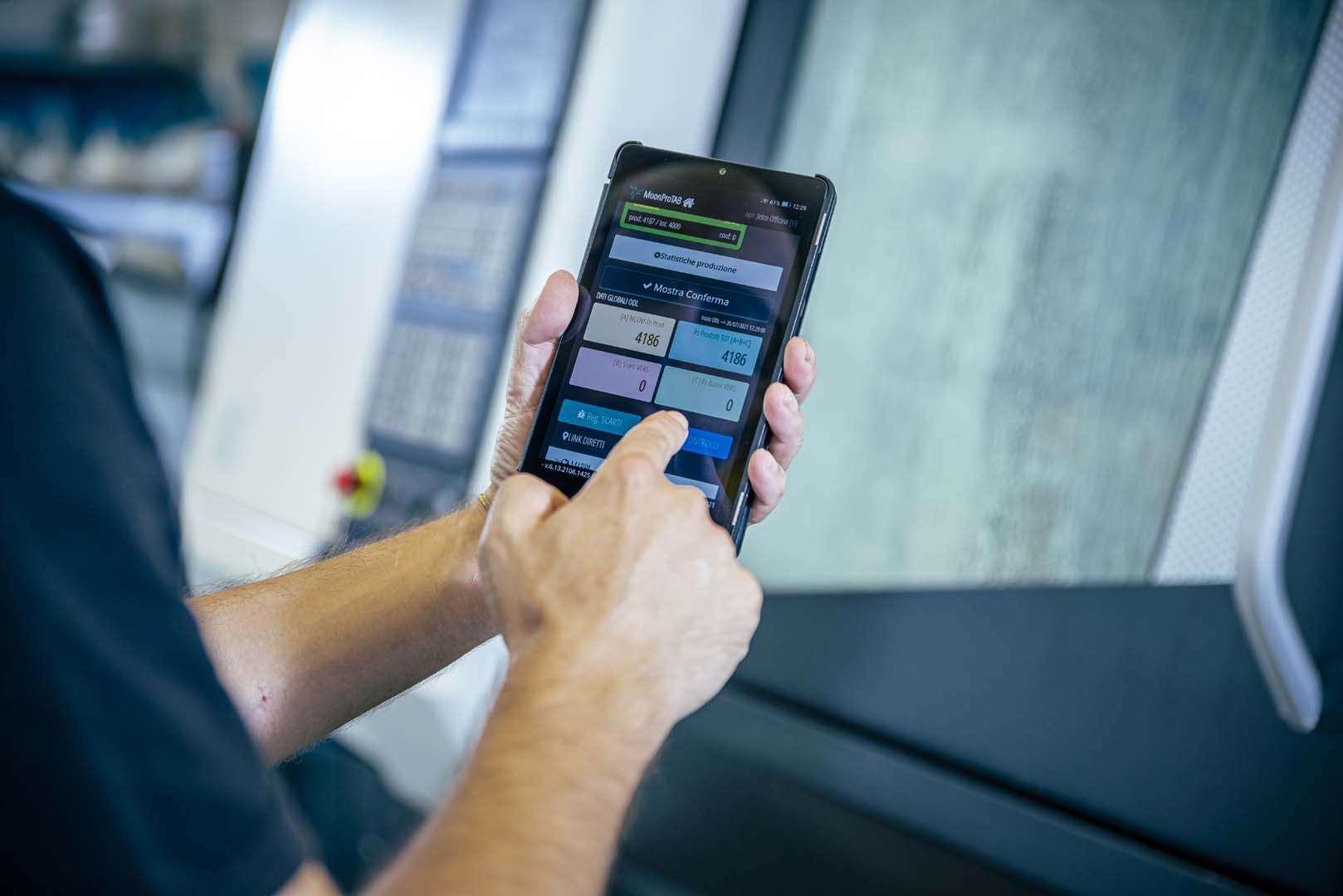

The process of "digital-transformation" has been already started in the 2016 for innovating the company to "INDUSTRY 4.0" and launch it into the future by updating and interconnecting all the production with our ERP software, the data are automatically recorded, guaranteeing the traceability of production batches at each stage of work. So, we are able to give a real-time traceability of our production: the raw material, the turning phase, the various heat treatments and the outer and inner grinding. The quality controls are strictly accomplished, accurate and reliable, they are also already done in digital way for the turning dept. and very soon for the grinding dept.

We have in every department some automatic storage machines linked to our ERP: for the raw material, for the tools of the CNC lathes and the grinding machines, for the semifinished and finished product, so, we know exactly in every moment about how much steel we have, how many and which tools, products and references are available. All the production, also the one of our outsourcing partners, is handled by bar-codes which allow us to monitoring and checking the batch of production through all their phases. Thanks to our MES we can check the real efficiency for each machinery of all our workshop and also the statistics of the maintenance, in order to reduce the production stops.

Automation

Inner grinding machine with anthropomorphic robot, production and quality control performed independently.

Analysis

Control and analysis of the statistics and of the efficiency for each machine.

Production batches

Progress of the production batches updated in real time.

Monitoring

Automatic data collection for each machine and also for each production batch.

Tool management

Automatic storage machine for both turning and grinding tools.

Steel

Storage machine interconnected with our ERP for the management and forecasting of the supply of raw material.

-

This email address is being protected from spambots. You need JavaScript enabled to view it.